Wireless Loadcell Link

Category

Application

The applications of load cell links are similar to those of load cell shackles, as both are used for measuring force and weight in various industrial and commercial settings. Some common applications of load cell links include:

Industrial lifting and rigging: Load cell links are used to measure the force exerted on lifting and rigging equipment, ensuring that loads are within safe working limits.

Crane and hoist monitoring: Load cell links are used to monitor the weight of loads being lifted by cranes and hoists, providing important data for safety and operational purposes.

Tension and compression testing: Load cell links are used in material testing applications to measure tension and compression forces, such as in the testing of cables, ropes, and structural components.

Offshore and marine applications: Load cell links are used in offshore and marine environments to measure the tension on mooring lines, anchor chains, and other rigging equipment.

Weighing and force measurement: Load cell links are used in various weighing and force measurement applications, such as in the monitoring of silo and hopper weights, vehicle weighing, and force measurement in industrial processes.

Overall, load cell links are versatile tools for measuring force and weight in a wide range of industrial and commercial applications, similar to load cell shackles.

Related Products

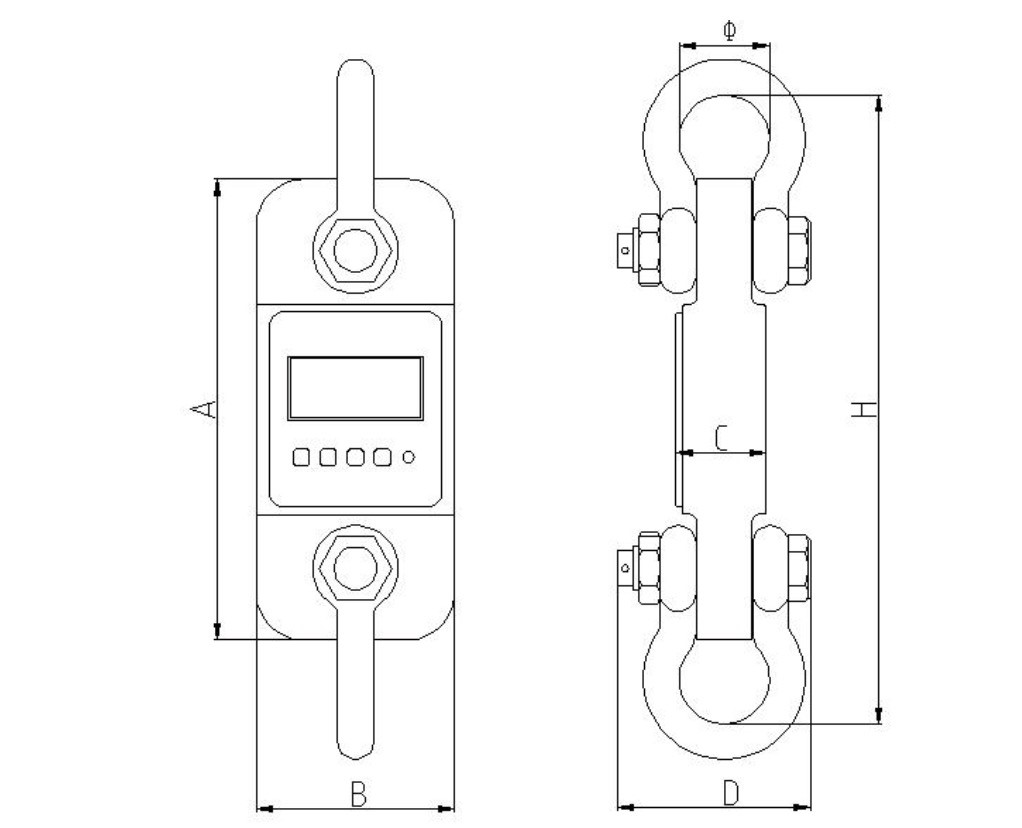

Wireless Loadcell Link Parameter

In addition to their outstanding design, quality, and sales performance, SCIC is dedicated to providing comprehensive after-sales services. This includes technical support, maintenance, and calibration services to ensure that customers continue to derive maximum value from their investment in SCIC load cell links. The commitment to customer satisfaction and support further enhances the appeal of SCIC load cell links as a trusted and reliable solution for force and weight measurement needs.

Table 1: Dimensions in mm (nominal with tolerance; client’s OEM available)

|

Model |

Capacity |

Div |

A |

B |

C |

D |

Φ |

H |

Material |

|

CS-SW6-01 |

1 |

0.5 |

245 |

112 |

37 |

190 |

43 |

335 |

Aluminum |

|

CS-SW6-02 |

2 |

1 |

245 |

116 |

37 |

190 |

43 |

335 |

Aluminum |

|

CS-SW6-03 |

3 |

1 |

260 |

123 |

37 |

195 |

51 |

365 |

Aluminum |

|

CS-SW6-05 |

5 |

2 |

285 |

123 |

57 |

210 |

58 |

405 |

Aluminum |

|

CS-SW6-10 |

10 |

5 |

320 |

120 |

57 |

230 |

92 |

535 |

Alloy steel |

|

CS-SW6-20 |

20 |

10 |

420 |

128 |

74 |

260 |

127 |

660 |

Alloy steel |

|

CS-SW6-30 |

30 |

10 |

420 |

138 |

82 |

280 |

146 |

740 |

Alloy steel |

|

CS-SW6-50 |

50 |

20 |

465 |

150 |

104 |

305 |

184 |

930 |

Alloy steel |

|

CS-SW6-100 |

100 |

50 |

570 |

190 |

132 |

366 |

229 |

1230 |

Alloy steel |

|

CS-SW6-150 |

150 |

50 |

610 |

234 |

136 |

400 |

252 |

1311 |

Alloy steel |

|

CS-SW6-200 |

200 |

100 |

725 |

265 |

183 |

440 |

280 |

1380 |

Alloy steel |

|

CS-SW6R-250 |

250 |

100 |

800 |

300 |

200 |

500 |

305 |

1880 |

Alloy steel |

|

CS-SW6R-300 |

300 |

200 |

880 |

345 |

200 |

500 |

305 |

1955 |

Alloy steel |

|

CS-SW6R-500 |

550 |

200 |

1000 |

570 |

200 |

500 |

305 |

2065 |

Alloy steel |

Table 2: Weight of loadcell links

|

Model |

1t |

2t |

3t |

5t |

10t |

20t |

30t |

|

Weight (kg) |

1.6 |

1.7 |

2.1 |

2.7 |

10.4 |

17.8 |

25 |

|

Weight with shackles(kg) |

3.1 |

3.2 |

4.6 |

6.3 |

24.8 |

48.6 |

87 |

|

Model |

50t |

100t |

150t |

200t |

250t |

300t |

500t |

|

Weight (kg) |

39 |

81 |

160 |

210 |

280 |

330 |

480 |

|

Weight with shackle (kg) |

128 |

321 |

720 |

776 |

980 |

1500 |

2200 |

Hazardous area Zone 1 and 2

Built-in-display option

Available with a range of displays to suit each application

Environmentally sealed to IP67 or IP68

Can be used singularly or in sets

Table 3: Wireless Loadcell Link Typical Specifications

|

Rated load: |

1/2/3/5/10/20/30/50/100/150/200/250/300/500T |

||

|

Battery type: |

18650 rechargeable batteries or polymer batteries (7.4v 2000 Mah) |

||

|

Proof load: |

150% of rated load |

Max. safety load: |

125% F.S. |

|

Ultimate load: |

400% F.S. |

Battery life: |

≥ 40 hours |

|

Power on zero range: |

20% F.S. |

Operating temp.: |

-10°C ~ +40°C |

|

Manual zero range: |

4% F.S. |

Operating humidity: |

≤ 85% RH under 20°C |

|

Tare range: |

20% F.S. |

Remote controller distance: |

Min. 15m |

|

Stable time: |

≤ 10 seconds |

System range: |

500~800m |

|

Overload indication: |

100% F.S. + 9e |

Telemetry frequency: |

470mhz |