Welded Steel Wide Mill Drag Chain for Mining Conveyors Wdh104, Wdh110, Wdh113, Wdh120, Wdh116

Welded Steel Wide Mill Drag Chain for Mining Conveyors Wdh104, Wdh110, Wdh113, Wdh120, Wdh116

Category

Flat link chain, mining flat link chain, mining round link chain, DIN 22255 flat link chains for use in continuous conveyors in mining, flight bar chain system, flat type chains, super flat type chains, double flat type chains

Application

Armored Face Conveyors (AFC),Beam Stage Loaders (BSL),road header machines

Flat type link chain was firstly introduced into mining industry by German chain making company back in 1985. The flat link chain consists of round links (DIN 22252) but every second link (the vertical link) is flat link which straight sides are of flattened finish per DIN 22255. Due to the less outer width of flat link (vertical) than round link (horizontal), the full flat link chain height is thus as lower as flat link size.

SCIC flat links are of forged making, and from the same material as round links.

Dimensionally, the flattened straight cross section area is larger than that of round link. When the full flat link chain goes through designed heat-treatment and final inspection & testing, the mechanical properties of flat links are well guaranteed per designated chain size & grade.

SCIC flat link chain is made according to China MT/T-929 standard and factory Technical Requirements, as well as to DIN 22255 or clients specs (which is to be specially agreed).

SCIC flat link chain is used for Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), road header machines and other equipment that requires this type of chain.

Anti-corrosive coatings (e.g., hot dipped galvanization) result in decreased chain mechanical properties, therefore the application of any anti-corrosive coatings shall subject to order agreement between buyer and SCIC.

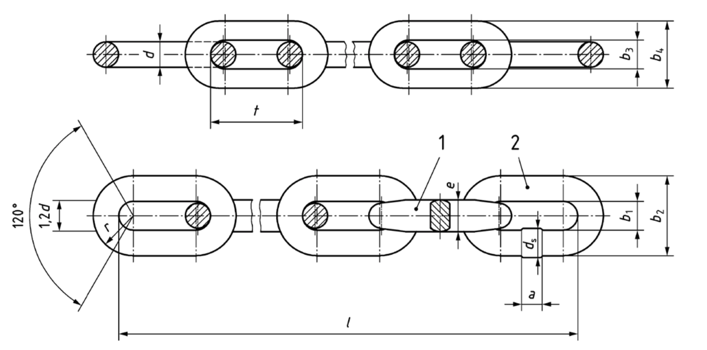

Figure 1: flat link chain

Table 1: flat link chain dimensions

|

chain size |

diameter |

width |

pitch |

round link width (mm) |

flat link width (mm) |

unit weight |

||||

|

nominal |

tolerance |

nominal |

tolerance |

inner b1 |

outer b2 |

inner b3 |

outer b4 |

|||

|

26 x 92 |

26 |

± 0.8 |

27 |

92 |

± 0.9 |

30 |

86 |

30 |

74 |

12.8 |

|

30 x 108 |

30 |

± 0.9 |

33 |

108 |

± 1.0 |

34 |

98 |

34 |

86 |

18.0 |

|

34 x 126 |

34 |

± 1.0 |

37 |

126 |

± 1.2 |

38 |

109 |

38 |

97 |

22.7 |

|

38 x 126 |

38 |

± 1.1 |

42 |

126 |

± 1.4 |

42 |

121 |

42 |

110 |

29.4 |

|

38 x 137 |

38 |

± 1.1 |

42 |

137 |

± 1.4 |

42 |

121 |

42 |

110 |

28.5 |

|

38 x 146 |

38 |

± 1.1 |

42 |

146 |

± 1.4 |

42 |

121 |

42 |

110 |

28.4 |

|

42 x 146 |

42 |

± 1.3 |

46 |

146 |

± 1.5 |

46 |

135 |

46 |

115 |

34.2 |

|

42 x 152 |

42 |

± 1.3 |

46 |

152 |

± 1.5 |

46 |

135 |

46 |

115 |

35.0 |

|

notes: larger size chain available upon inquiry. |

||||||||||

Table 2: flat link chain mechanical properties

|

chain size |

chain grade |

test force |

elongation under test force |

breaking force |

elongation at fracture |

minimum deflection |

|

26 x 92 |

S |

540 |

1.4 |

670 |

11 |

26 |

|

SC |

680 |

1.6 |

850 |

|||

|

30 x 108 |

S |

710 |

1.4 |

890 |

11 |

30 |

|

SC |

900 |

1.6 |

1130 |

|||

|

34 x 126 |

S |

900 |

1.4 |

1140 |

11 |

34 |

|

SC |

1160 |

1.6 |

1450 |

|||

|

38 x 126 |

S |

1130 |

1.4 |

1420 |

11 |

38 |

|

SC |

1450 |

1.6 |

1810 |

|||

|

42 x 146 |

S |

1390 |

1.4 |

1740 |

11 |

42 |

|

SC |

1770 |

1.6 |

2220 |

|||

|

note: deflection not applicable to forged flat link |

||||||