Popular Design for Single Leg Chain - Conveyor and elevator chains – Chigong

Popular Design for Single Leg Chain - Conveyor and elevator chains – Chigong Detail:

Category

Lifting chain, short link chain, long link chain, round link chain, chain lifting, lifting chains, Grade 50 chain, Grade 70 chain, DIN 764-1, DIN 764-2, DIN 766, Round steel link chains for chain conveyor Conveyor chain, bucket elevator chain, alloy steel chain

Application

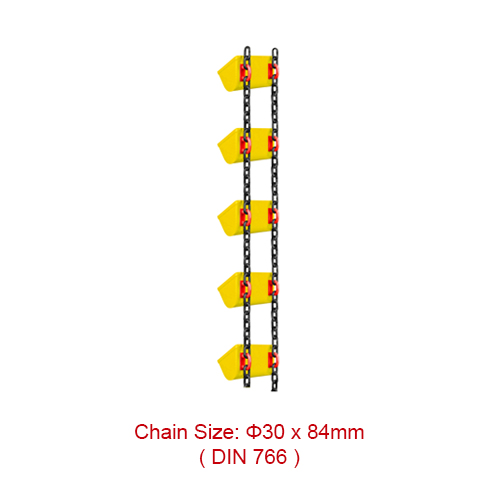

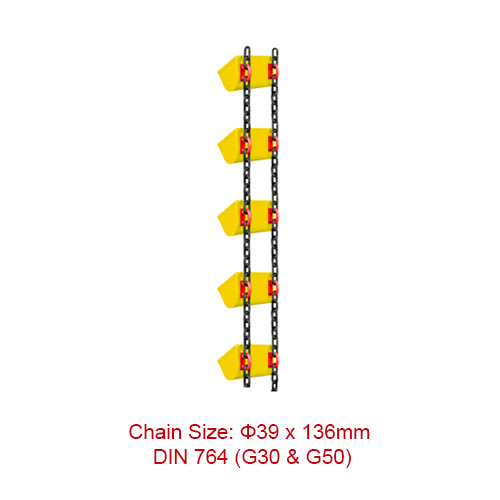

Bucket elevator, conveyor, scraper Chains for bucket elevator, conveyor and scraper SCIC produce round steel link chains per DIN 764 (G30 & G50, 2010 version) and DIN 766 (2015 version) standards, for applications in bucket elevator, conveyor and scraper. Chains specified here shall not be used as lifting accessories, slings or any other overhead hoisting.

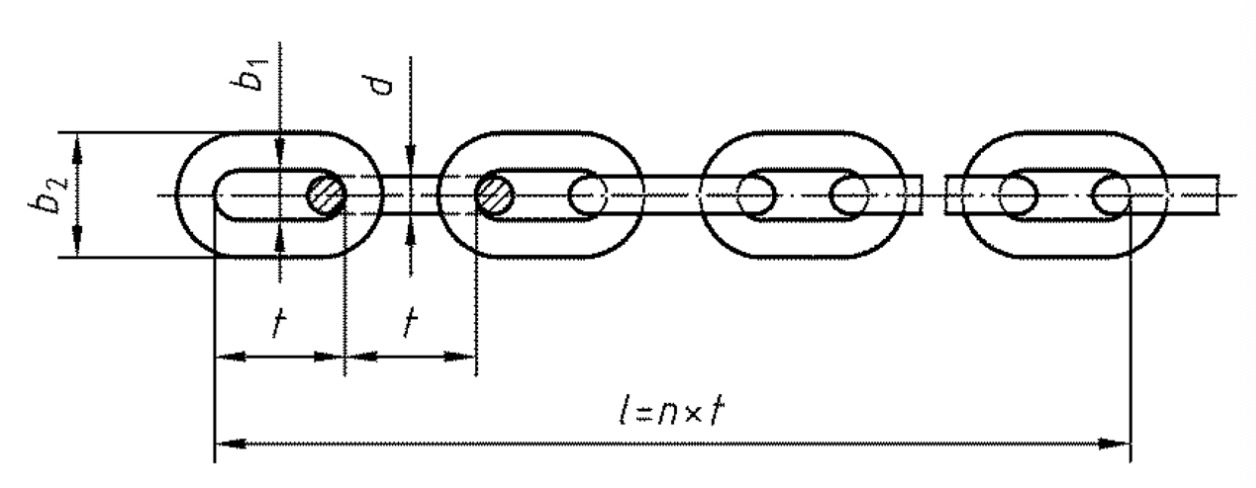

Figure 1: DIN 764 and DIN 766 round steel link chain dimensions

Table 1: DIN 764 round steel link chain (G30 & G50) dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

classA |

class B |

|||||||||

|

10 x 35 |

10 |

± 0.4 |

35 |

+0.6/-0.2 |

14.0 |

36 |

385 |

+2/-1 |

+3/-1 |

2.1 |

|

13 x 45 |

13 |

± 0.5 |

45 |

+0.8/-0.3 |

18.0 |

47 |

495 |

+3/-1 |

+4/-1 |

3.5 |

|

16 x 56 |

16 |

± 0.6 |

56 |

+1.0/-0.3 |

22.0 |

58 |

616 |

+3/-1 |

+5/-2 |

5.3 |

|

18 x 63 |

18 |

± 0.9 |

63 |

+1.1/-0.4 |

24.0 |

65 |

693 |

+4/-1 |

+6/-2 |

6.7 |

|

20 x 70 |

20 |

± 1.0 |

70 |

+1.3/-0.4 |

27.0 |

72 |

770 |

+4/-1 |

+6/-2 |

8.3 |

|

23 x 80 |

23 |

± 1.2 |

80 |

+1.4/-0.5 |

31.0 |

83 |

880 |

+5/-2 |

+7/-2 |

11.0 |

|

26 x 91 |

26 |

± 1.3 |

91 |

+1.6/-0.5 |

35.0 |

94 |

1001 |

+5/-2 |

+8/-3 |

14.0 |

|

30 x 105 |

30 |

± 1.5 |

105 |

+1.9/-0.6 |

39.0 |

108 |

1155 |

+6/-2 |

+9/-3 |

18.5 |

|

33 x 115 |

33 |

± 1.7 |

115 |

+2.1/-0.7 |

43.0 |

119 |

1265 |

+7/-2 |

+10/-3 |

22.5 |

|

36 x 126 |

36 |

± 1.8 |

126 |

+2.3/-0.8 |

47.0 |

130 |

1386 |

+7/-2 |

+11/-4 |

27.0 |

|

39 x 136 |

39 |

± 2.0 |

136 |

+2.4/-0.8 |

51.0 |

140 |

1496 |

+8/-3 |

+12/-4 |

31.5 |

|

42 x 147 |

42 |

± 2.1 |

147 |

+2.6/-0.9 |

55.0 |

151 |

1617 |

+9/-3 |

+13/-4 |

36.5 |

Table 2: DIN 766 round steel link chain dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

class A |

class B |

|||||||||

|

10 x 28 |

10 |

± 0.4 |

28 |

+0.5/-0.3 |

14.0 |

36 |

308 |

+2 /-1 |

+2 /-1 |

2.3 |

|

13 x 36 |

13 |

± 0.5 |

36 |

+0.6/-0.3 |

18.0 |

47 |

396 |

+2 /-1 |

+3 /-2 |

3.9 |

|

16 x 45 |

16 |

± 0.6 |

45 |

+0.8/-0.4 |

22.5 |

58 |

496 |

+3 /-1 |

+4 /-2 |

5.9 |

|

18 x 50 |

18 |

± 0.9 |

50 |

+0.9/-0.5 |

25.0 |

65 |

550 |

+3 /-1 |

+4 /-2 |

7.5 |

|

20 x 56 |

20 |

± 1.0 |

56 |

+1.0/-0.5 |

28.0 |

72 |

616 |

+3 /-2 |

+5 /-2 |

9.2 |

|

23 x 64 |

23 |

± 1.2 |

64 |

+1.2/-0.6 |

32.0 |

83 |

704 |

+4 /-2 |

+6 /-3 |

12.0 |

|

26 x 73 |

26 |

± 1.3 |

73 |

+1.3/-0.7 |

34.0 |

94 |

803 |

+4 /-2 |

+6 /-3 |

15.5 |

|

30 x 84 |

30 |

± 1.5 |

84 |

+1.5/-0.8 |

39.0 |

108 |

924 |

+5 /-2 |

+7 /-4 |

20.5 |

|

33 x 92 |

33 |

± 1.7 |

92 |

+1.7/-0.8 |

43.0 |

119 |

1012 |

+5 /-3 |

+8 /-4 |

25.0 |

|

36 x 101 |

36 |

± 1.8 |

101 |

+1.8/-0.9 |

47.0 |

130 |

1111 |

+6 /-3 |

+9 /-4 |

29.5 |

|

39 x 109 |

39 |

± 2.0 |

109 |

+2.0/-1.0 |

50.5 |

140 |

1199 |

+6 /-3 |

+10 /-5 |

35.0 |

|

42 x 118 |

42 |

± 2.1 |

118 |

+2.1/-1.1 |

54.5 |

151 |

1298 |

+7 /-4 |

+10 /-5 |

40.5 |

Table 3: DIN 764 round steel link chain (G30 & G50) working force and mechanical properties

|

nominal size |

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|||||

|

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

|

|

10 x 35 |

12.5 |

20 |

36 |

56 |

50 |

80 |

10 |

10 |

20 |

15 |

|

13 x 45 |

20 |

32 |

56 |

90 |

80 |

125 |

13 |

13 |

||

|

16 x 56 |

32 |

50 |

90 |

140 |

125 |

200 |

16 |

16 |

||

|

18 x 63 |

40 |

63 |

110 |

180 |

160 |

250 |

18 |

18 |

||

|

20 x 70 |

50 |

80 |

140 |

220 |

200 |

320 |

20 |

20 |

||

|

23 x 80 |

63 |

100 |

180 |

280 |

250 |

400 |

23 |

23 |

||

|

26 x 91 |

80 |

125 |

220 |

360 |

320 |

500 |

26 |

26 |

||

|

30 x 105 |

110 |

180 |

320 |

500 |

450 |

710 |

30 |

30 |

||

|

33 x 115 |

125 |

200 |

360 |

560 |

500 |

800 |

33 |

33 |

||

|

36 x 126 |

160 |

250 |

450 |

710 |

630 |

1000 |

36 |

36 |

||

|

39 x 136 |

180 |

280 |

500 |

800 |

710 |

1100 |

39 |

39 |

||

|

42 x 147 |

220 |

360 |

630 |

1000 |

900 |

1400 |

42 |

42 |

||

Table 4: DIN 766 round steel link chain working force and mechanical properties

|

nominal size

|

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|

|

vertical |

horizontal |

|||||

|

10 x 28 |

10 |

12.5 |

36 |

50 |

8 |

20 |

|

13 x 36 |

16 |

20 |

56 |

80 |

10 |

|

|

16 x 45 |

25 |

32 |

90 |

125 |

13 |

|

|

18 x 50 |

32 |

40 |

110 |

160 |

14 |

|

|

20 x 56 |

40 |

50 |

140 |

200 |

16 |

|

|

23 x 64 |

50 |

63 |

180 |

250 |

18 |

|

|

26 x 73 |

63 |

80 |

220 |

320 |

21 |

|

|

30 x 84 |

90 |

110 |

320 |

450 |

24 |

|

|

33 x 92 |

110 |

130 |

380 |

530 |

26 |

|

|

36 x 101 |

125 |

160 |

450 |

630 |

29 |

|

|

39 x 109 |

150 |

190 |

530 |

750 |

31 |

|

|

42 x 118 |

180 |

220 |

630 |

900 |

34 |

|

Product detail pictures:

Related Product Guide:

The organization upholds the philosophy of "Be No.1 in good quality, be rooted on credit history and trustworthiness for growth", will keep on to provide previous and new customers from home and overseas whole-heatedly for Popular Design for Single Leg Chain - Conveyor and elevator chains – Chigong, The product will supply to all over the world, such as: Manila, Norway, Ecuador, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!