OEM/ODM China 26 Stainless Steel Chain - Conveyor and elevator chains – Chigong

OEM/ODM China 26 Stainless Steel Chain - Conveyor and elevator chains – Chigong Detail:

Category

Lifting chain, short link chain, long link chain, round link chain, chain lifting, lifting chains, Grade 50 chain, Grade 70 chain, DIN 764-1, DIN 764-2, DIN 766, Round steel link chains for chain conveyor Conveyor chain, bucket elevator chain, alloy steel chain

Application

Bucket elevator, conveyor, scraper Chains for bucket elevator, conveyor and scraper SCIC produce round steel link chains per DIN 764 (G30 & G50, 2010 version) and DIN 766 (2015 version) standards, for applications in bucket elevator, conveyor and scraper. Chains specified here shall not be used as lifting accessories, slings or any other overhead hoisting.

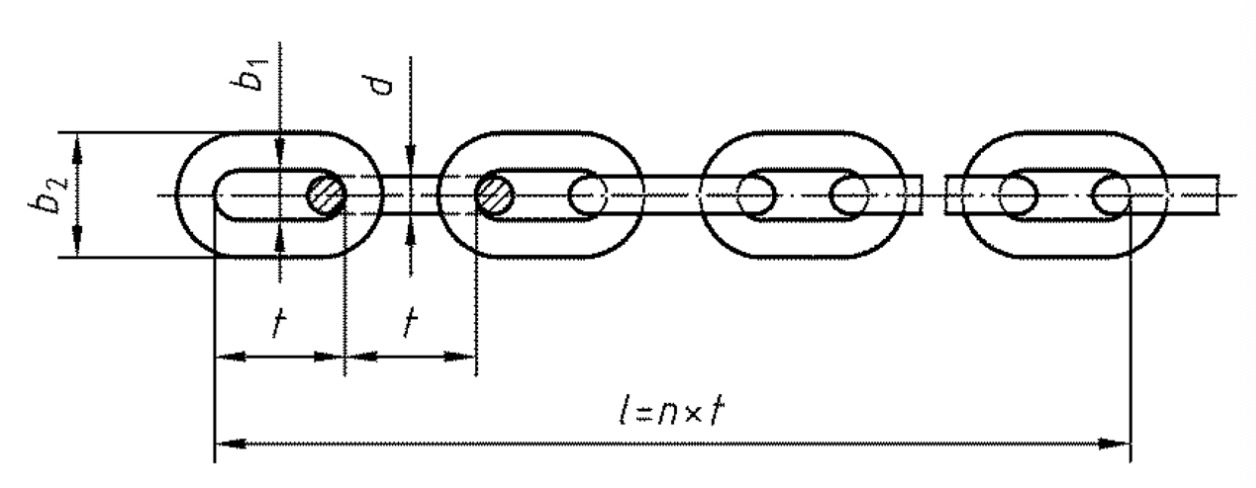

Figure 1: DIN 764 and DIN 766 round steel link chain dimensions

Table 1: DIN 764 round steel link chain (G30 & G50) dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

classA |

class B |

|||||||||

|

10 x 35 |

10 |

± 0.4 |

35 |

+0.6/-0.2 |

14.0 |

36 |

385 |

+2/-1 |

+3/-1 |

2.1 |

|

13 x 45 |

13 |

± 0.5 |

45 |

+0.8/-0.3 |

18.0 |

47 |

495 |

+3/-1 |

+4/-1 |

3.5 |

|

16 x 56 |

16 |

± 0.6 |

56 |

+1.0/-0.3 |

22.0 |

58 |

616 |

+3/-1 |

+5/-2 |

5.3 |

|

18 x 63 |

18 |

± 0.9 |

63 |

+1.1/-0.4 |

24.0 |

65 |

693 |

+4/-1 |

+6/-2 |

6.7 |

|

20 x 70 |

20 |

± 1.0 |

70 |

+1.3/-0.4 |

27.0 |

72 |

770 |

+4/-1 |

+6/-2 |

8.3 |

|

23 x 80 |

23 |

± 1.2 |

80 |

+1.4/-0.5 |

31.0 |

83 |

880 |

+5/-2 |

+7/-2 |

11.0 |

|

26 x 91 |

26 |

± 1.3 |

91 |

+1.6/-0.5 |

35.0 |

94 |

1001 |

+5/-2 |

+8/-3 |

14.0 |

|

30 x 105 |

30 |

± 1.5 |

105 |

+1.9/-0.6 |

39.0 |

108 |

1155 |

+6/-2 |

+9/-3 |

18.5 |

|

33 x 115 |

33 |

± 1.7 |

115 |

+2.1/-0.7 |

43.0 |

119 |

1265 |

+7/-2 |

+10/-3 |

22.5 |

|

36 x 126 |

36 |

± 1.8 |

126 |

+2.3/-0.8 |

47.0 |

130 |

1386 |

+7/-2 |

+11/-4 |

27.0 |

|

39 x 136 |

39 |

± 2.0 |

136 |

+2.4/-0.8 |

51.0 |

140 |

1496 |

+8/-3 |

+12/-4 |

31.5 |

|

42 x 147 |

42 |

± 2.1 |

147 |

+2.6/-0.9 |

55.0 |

151 |

1617 |

+9/-3 |

+13/-4 |

36.5 |

Table 2: DIN 766 round steel link chain dimensions (mm)

|

nominal |

diameter |

pitch |

width |

gauge length (11-link) |

kg/m |

|||||

|

d x t |

d |

tolerance |

t |

tolerance |

inner |

outer |

l |

tolerance |

||

|

class A |

class B |

|||||||||

|

10 x 28 |

10 |

± 0.4 |

28 |

+0.5/-0.3 |

14.0 |

36 |

308 |

+2 /-1 |

+2 /-1 |

2.3 |

|

13 x 36 |

13 |

± 0.5 |

36 |

+0.6/-0.3 |

18.0 |

47 |

396 |

+2 /-1 |

+3 /-2 |

3.9 |

|

16 x 45 |

16 |

± 0.6 |

45 |

+0.8/-0.4 |

22.5 |

58 |

496 |

+3 /-1 |

+4 /-2 |

5.9 |

|

18 x 50 |

18 |

± 0.9 |

50 |

+0.9/-0.5 |

25.0 |

65 |

550 |

+3 /-1 |

+4 /-2 |

7.5 |

|

20 x 56 |

20 |

± 1.0 |

56 |

+1.0/-0.5 |

28.0 |

72 |

616 |

+3 /-2 |

+5 /-2 |

9.2 |

|

23 x 64 |

23 |

± 1.2 |

64 |

+1.2/-0.6 |

32.0 |

83 |

704 |

+4 /-2 |

+6 /-3 |

12.0 |

|

26 x 73 |

26 |

± 1.3 |

73 |

+1.3/-0.7 |

34.0 |

94 |

803 |

+4 /-2 |

+6 /-3 |

15.5 |

|

30 x 84 |

30 |

± 1.5 |

84 |

+1.5/-0.8 |

39.0 |

108 |

924 |

+5 /-2 |

+7 /-4 |

20.5 |

|

33 x 92 |

33 |

± 1.7 |

92 |

+1.7/-0.8 |

43.0 |

119 |

1012 |

+5 /-3 |

+8 /-4 |

25.0 |

|

36 x 101 |

36 |

± 1.8 |

101 |

+1.8/-0.9 |

47.0 |

130 |

1111 |

+6 /-3 |

+9 /-4 |

29.5 |

|

39 x 109 |

39 |

± 2.0 |

109 |

+2.0/-1.0 |

50.5 |

140 |

1199 |

+6 /-3 |

+10 /-5 |

35.0 |

|

42 x 118 |

42 |

± 2.1 |

118 |

+2.1/-1.1 |

54.5 |

151 |

1298 |

+7 /-4 |

+10 /-5 |

40.5 |

Table 3: DIN 764 round steel link chain (G30 & G50) working force and mechanical properties

|

nominal size |

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|||||

|

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

G30 |

G50 |

|

|

10 x 35 |

12.5 |

20 |

36 |

56 |

50 |

80 |

10 |

10 |

20 |

15 |

|

13 x 45 |

20 |

32 |

56 |

90 |

80 |

125 |

13 |

13 |

||

|

16 x 56 |

32 |

50 |

90 |

140 |

125 |

200 |

16 |

16 |

||

|

18 x 63 |

40 |

63 |

110 |

180 |

160 |

250 |

18 |

18 |

||

|

20 x 70 |

50 |

80 |

140 |

220 |

200 |

320 |

20 |

20 |

||

|

23 x 80 |

63 |

100 |

180 |

280 |

250 |

400 |

23 |

23 |

||

|

26 x 91 |

80 |

125 |

220 |

360 |

320 |

500 |

26 |

26 |

||

|

30 x 105 |

110 |

180 |

320 |

500 |

450 |

710 |

30 |

30 |

||

|

33 x 115 |

125 |

200 |

360 |

560 |

500 |

800 |

33 |

33 |

||

|

36 x 126 |

160 |

250 |

450 |

710 |

630 |

1000 |

36 |

36 |

||

|

39 x 136 |

180 |

280 |

500 |

800 |

710 |

1100 |

39 |

39 |

||

|

42 x 147 |

220 |

360 |

630 |

1000 |

900 |

1400 |

42 |

42 |

||

Table 4: DIN 766 round steel link chain working force and mechanical properties

|

nominal size

|

working force |

manufacturing |

breaking force |

bend deflection |

total ultimate elongation |

|

|

vertical |

horizontal |

|||||

|

10 x 28 |

10 |

12.5 |

36 |

50 |

8 |

20 |

|

13 x 36 |

16 |

20 |

56 |

80 |

10 |

|

|

16 x 45 |

25 |

32 |

90 |

125 |

13 |

|

|

18 x 50 |

32 |

40 |

110 |

160 |

14 |

|

|

20 x 56 |

40 |

50 |

140 |

200 |

16 |

|

|

23 x 64 |

50 |

63 |

180 |

250 |

18 |

|

|

26 x 73 |

63 |

80 |

220 |

320 |

21 |

|

|

30 x 84 |

90 |

110 |

320 |

450 |

24 |

|

|

33 x 92 |

110 |

130 |

380 |

530 |

26 |

|

|

36 x 101 |

125 |

160 |

450 |

630 |

29 |

|

|

39 x 109 |

150 |

190 |

530 |

750 |

31 |

|

|

42 x 118 |

180 |

220 |

630 |

900 |

34 |

|

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for OEM/ODM China 26 Stainless Steel Chain - Conveyor and elevator chains – Chigong, The product will supply to all over the world, such as: Peru, London, Milan, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.