Links and rings are a rather basic type of rigging hardware, consisting of just a single metal loop. Maybe you’ve seen a master ring lying around the shop or an oblong link hanging from a crane hook. However, if you’re new to the rigging industry or haven’t used a link or ring before, it may not be entirely clear why these simple devices are so essential when rigging an overhead lift.

We have noticed that when it comes to links and rings, a lot of specific and technical information is available online. However, general information on what these devices are and what they are used for is virtually non-existent.

For customers out there that may be new to rigging-related products, starting with basic and application-based information is necessary before getting into the more complicated stuff. Which is why we’ve written this article.

In this article, you can expect to learn:

● What links and rings are and what they’re used for

● What the different types of links and rings are

● Links and rings markings / identification

● Links and rings removal from service criteria

1. What are Links and Rings?

Links and rings are basic but essential components in lifting and rigging applications. They’re closed-loop devices—similar to an eye—that are used to make connection points in rigging and sling assemblies including chain slings, wire rope slings, webbing slings, etc.

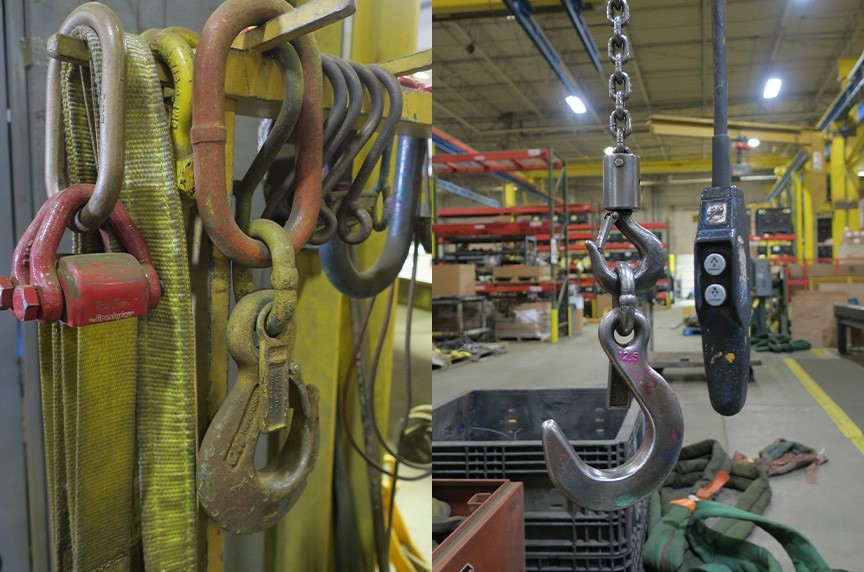

Links and rings are commonly used as the connection point in multiple-leg sling assemblies—typically chain or wire rope. They may be used as the connection point for one, two, three, or four sling-leg configurations.

Master links and rings—oblong master links, master rings, and pear-shaped master links—are also referred to as collector rings or collector links, as they “collect” multiple sling legs into a single link.

In addition to use in sling assemblies, links and rings can also be used as a connection point between virtually any two parts of a rigging assembly. For example, you may use a link or ring to connect a:

- Sling to a hook

- Link to a sling hook

2. Types of Links and Rings

There are several different types of links and rings that can be used in an assembly. The most commonly used types of links and rings are: Oblong master links, Master link sub-assemblies, Pear-shaped links, Master rings, Coupling links.

Oblong master links are oblong, permanently closed loops that are often found at the top of a multiple-leg chain sling assembly or wire rope bridle. In this case, the oblong master link is the connection point that collects the legs that make up the sling assembly.

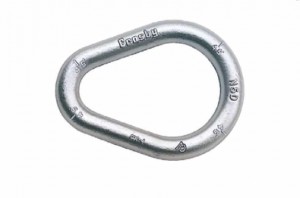

Master rings are circular, permanently closed rings. Like a master link, they can be used with wire rope bridles, chain sling assemblies, and other rigging connection points. While master rings can be used to accommodate multiple-leg assemblies, it is less common to see a master ring as the collector link than it is to see an oblong master link in that position.

The pear shape of these links makes them ideal for use with very narrow hooks. In some cases, a pear-shaped link will be a snugger fit than an oblong master link, which eliminates load movement from side-to-side on the surface of the hook.

Coupling links may be mechanical or welded and are primarily used to connect a portion of chain to a master link or to a fitting. They may also be used to create a connection between master links, hooks, or other pieces of hardware.

If there are more than two sling legs in an assembly, a master link sub-assembly may be used in place of a single master link. While it is possible to have three to four legs attached to a single master link, this often requires extremely heavy, thick master links that are difficult to manage.

Sub-assemblies consist of two master coupling links attached to an oblong master link. Rather than attaching all four sling legs to a master link, they can now be split between the two sub-assembly links.

The use of sub-assemblies helps to reduce the size of the master link—extremely large master links can be upwards of 3 inches in diameter—while maintaining a Working Load Limit (WLL) comparable to a much larger master link.

Oblong master links are oblong, permanently closed loops that are often found at the top of a multiple-leg chain sling assembly or wire rope bridle. In this case, the oblong master link is the connection point that collects the legs that make up the sling assembly.

While they are commonly used as connection points in multiple-leg slings, oblong master links also serve as connection points between rigging equipment and hardware.

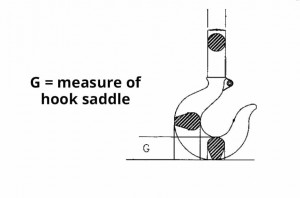

Because of their oblong shape, they are ideal for attaching to crane hooks that have a large measurement from the bearing of the bowl to the bottom of the hook—known as the hook saddle. Crane hooks typically measure larger in the hook saddle area than in the width area.

Oblong master links can also be used to connect a shackle to a crane hook, a hook to a shackle, and other various rigging assemblies.

While they are commonly used as connection points in multiple-leg slings, oblong master links also serve as connection points between rigging equipment and hardware.

Because of their oblong shape, they are ideal for attaching to crane hooks that have a large measurement from the bearing of the bowl to the bottom of the hook—known as the hook saddle. Crane hooks typically measure larger in the hook saddle area than in the width area.

Oblong master links can also be used to connect a shackle to a crane hook, a hook to a shackle, and other various rigging assemblies.

Pear-shaped links are similar to an oblong master link but, like the name suggests, are pear-shaped rather than oblong. Pear-shaped links—like oblong master links— are also used for multiple-leg chain slings, wire rope bridles, and various rigging connection points. However, pear-shaped links are limited to accommodating smaller sling assemblies with two legs or less.

The round shape of a master ring makes it less ideal than an oblong master link for connecting to large, deep crane hooks. Master rings are most often used in fabrication or small machine shops and are otherwise, rarely used. In many cases, an oblong master link could be applied instead.

Mechanical coupling links consist of multiple parts that may include a bushing, bolt, and spring at the center. These mechanical coupling links act as attachment points that hinge at the center.

Hammerlok® Assembled and Disassembled

Three common brand names for mechanical coupling links include:

- Hammerlok® (CM brand)

- Kuplex® Kuplok® (Peerless brand)

- Lok-a-Loy® (Crosby brand)

A Kuplex® Kupler®, also a Peerless product, is another common type of mechanical coupling link. These coupling links have a slightly different look resembling a shackle. There is only one body half through which a connection is made with load pin and retaining pin. Given that there are not two body halves, a Kuplex® Kupler® does not hinge at the center.

Welded coupling links, like every other link in a chain, are connected to the master link or end fitting and welded shut to form a connection.

The image featured in this section shows two different ways a welded coupling link can be utilized. In the left picture, the link is permanently connected to an eye hook and used to connect the device to a swivel hook. On the right, the welded coupling links are used to secure the chain legs and grab hooks to the master link.

Chain Sling Assembly Using Several Kuplex® Kupler® Links

3. Links and Rings Markings / Identification

According to ASME B30.26 Rigging Hardware, each link, master link subassembly, and ring shall be durably marked by the manufacturer to show:

- Name or trademark of manufacturer

- Size or rated load

- Grade, if required to identify rated load

4. Links and Rings Removal From Service Criteria

During the course of an inspection, remove any links, master link sub-assemblies, and rings from service if any of the conditions listed in ASME B30.26 Rigging Hardware are present.

- Missing or illegible identification

- Indications of heat damage, including weld spatter or arc strikes

- Excessive pitting or corrosion

- Bent, twisted, distorted, stretched, elongated, cracked, or broken load-bearing components

- Excessive nicks or gouges

- A 10% reduction of the original or catalog dimension at any point

- Evidence of unauthorized welding or modification

- Other conditions, including visible damage that cause doubt as to continued use

If any of the above conditions are present, the device must be removed from service and shall only be returned to service if/when approved by a qualified person.

5. Wrapping It Up

We hope that this article helped to provide you with a base-level understanding of what links and rings are, what they are used for, and related identification and inspection criteria in ASME B30.26 Rigging Hardware.

To sum it up, links and rings serve as connection points in a rigging assembly or multiple-leg sling assembly. While there are several different types of links and rings used in rigging, oblong master links are the most versatile and commonly used as collector rings.

Coupling links are used to connect portions of chain to an end fitting or collector ring and may be mechanical or welded.

Like any other piece of rigging hardware, be sure to abide by relevant ASME standards and removal from service criteria.

(with courtesy of Mazzella)

Post time: Jun-17-2022