Hardness Requirements and Strength

Round link chains for bucket elevators and Submerged Scraper Conveyor typically require a high hardness level to resist harsh wear and tear. Case-hardened chains, for example, can reach surface hardness levels of 57-63 HRC.

The tensile strength of these round link conveyor chains is crucial for handling heavy loads. Chains with case hardening treatment can have a breaking force of 300-350 N/mm²

Achieving Longer Lifespan of Chain Links

1. Material Quality is a start to determine chains service life, so chain manufacture need to use high-quality materials like manganese steel or chromium-nickel steel for enhanced wear resistance.

2. Proper Installation plays very important role in chains lifespan: Ensure professional installation to avoid issues like sagging or misalignment

3. Regular Maintenance is a must: conveyor operators need to conduct periodic inspections, clean the chains to remove dirt and debris, and address any signs of wear or damage promptly. Replacement of over worn chain strands can never ever been postponed for cost saving, as the failure of conveyor and bucket elevator due to broken chain strands will result in times higher cost.

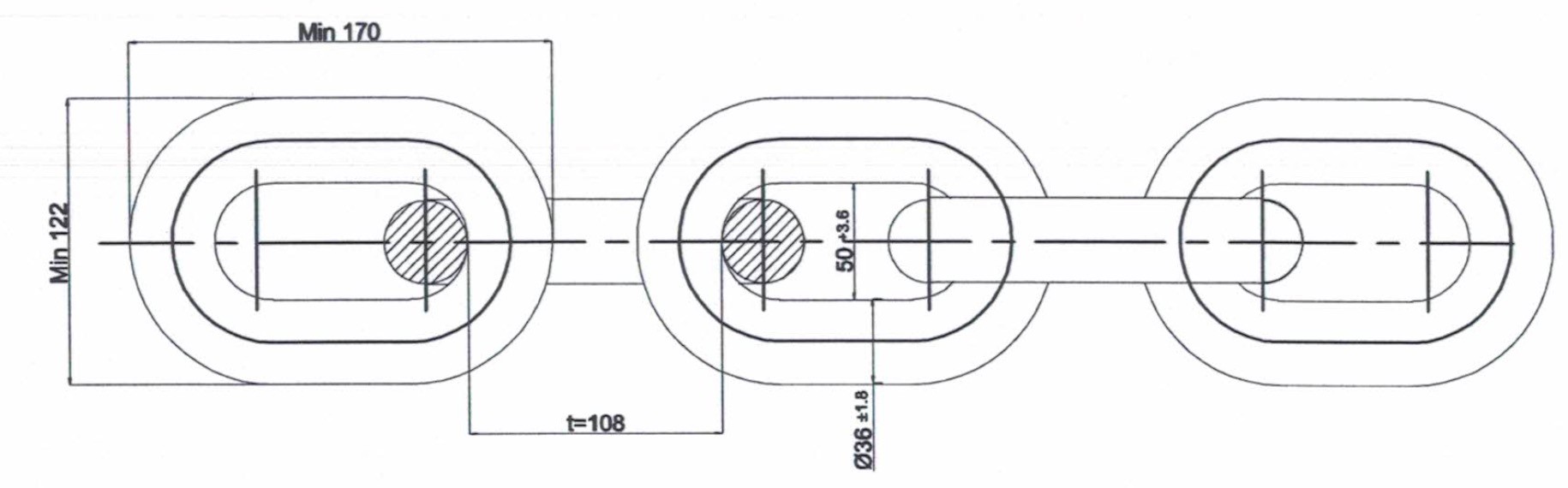

Ensuring Accuracy of Round Link Chains Dimensions

1. Precision Production: chain supplier shall ensure that the chain links be manufactured with high precision to maintain uniformity and accuracy. This very much depends on machinery conditions and workers skill in chain making.

2. Calibration of chain links during manufacture: factory workers and inspectors shall check and calibrate the chain strands to ensure all chain strands in pairs and meet designed tolerance.

Post time: Dec-16-2024