When it comes to selecting the appropriate bucket elevator round link chain, understanding the specifications and applications of DIN 764 and DIN 766 standards is crucial. These standards provide essential dimensions and performance characteristics that ensure the durability and efficiency of your bucket elevator system.

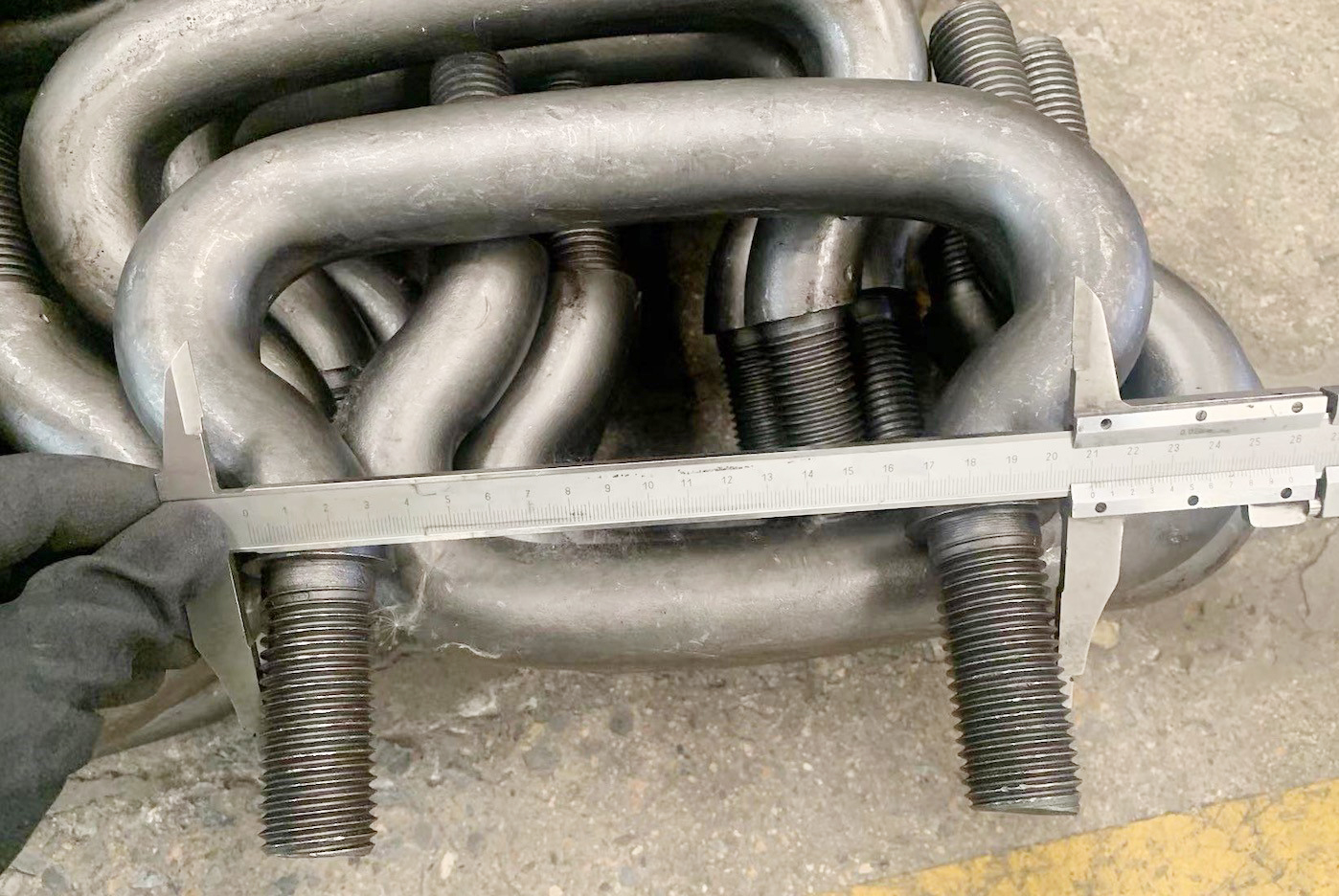

Our Round Link Chain Brackets (chain shackles or chain bows) are manufactured in accordance with DIN 745 and DIN 5699 standards. This compliance ensures that our chain brackets can withstand the toughest conditions while maintaining structural integrity.

Hardness Testing: Each batch of our chain brackets undergoes rigorous hardness testing, with case hardening surface hardness upto 55-60 HRC and tensile strength 300-350N/mm2. This process enhances their resistance to wear and tear, making them ideal for heavy-duty applications.

Material Properties: Crafted from high-grade alloy steel materials such as 20CrNiMo, SAE8620 or 23MnNiMoCr54, our Round Link Chain Brackets exhibit exceptional strength and corrosion resistance and high service ambient temperature. This ensures longevity and reliability, even in the most challenging environments.

Size Guide for Optimal Selection: We provide a comprehensive size guide to help you select the perfect Round Link Chain Brackets for your specific bucket elevator needs, to suit round link chains DIN 764 such as 10x40mm, 13x45mm, 16x56mm, 18x63mm, 36x126mm, etc. This ensures a perfect fit and optimal performance, tailored to your operational requirements.

Selecting the right bucket elevator round link chains and chain brackets involves a thorough understanding of DIN 764, DIN 766, DIN 745 and DIN 5699 standards, their dimensions, applications, and the importance of chain hardness testing. By considering these factors, you can ensure the reliability and efficiency of your bucket elevator system, ultimately enhancing your operational productivity.

Post time: Oct-14-2024