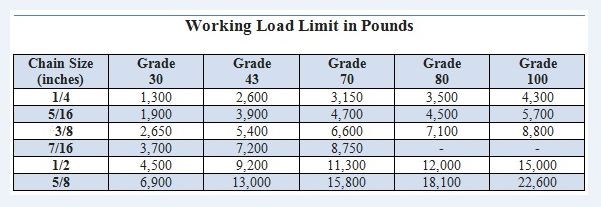

1. Working Load Limit for Round Link Steel Chains

Whether you transport machinery, use tow chains, or are in the logging industry, it's important to know the working load limits of chain you are using. Chains have a working load limit- or WLL- of approximately one forth of their break strengths (the amount of force the chains can withstand before they break).

The chain grade and diameter determines the working load limit of the chain. Chain is embossed with both the grade and size so you can determine its WLL using this chart.

2. Types of chain

Grade 30 is a multipurpose, economical chain. Also known as Grade 30 Proof Coil Chain, people use this product in a variety of industries and jobs, including light construction, barrier chains, and in the marine industry. It is not safe for overhead lifting. Grade 30 chain is embossed using a 3, 30, or 300.

Also called Grade 43 High Test Chain or Grade 43 Tow Chain, this is common in the towing and logging industries. Never use this chain for overhead lifting. This chain includes designs embossed using a 43 or a G4.

Grade 70 Transport Chain, also called "Grade 70 Truckers Chain," works in securing loads for over-the-road hauling. Never use this chain for any overhead lifting. This chain include designs embossed using a 7, 70, or 700.

Grade 80 Alloy Chain works for overhead lifting due to its heat-treated design. People commonly use this type of chain as a heavy duty tow chain. Grade 80 chain include designs embossed using an 8, 80, or 800.

Considered premium quality chain, it offers about a 25% higher work load limit over Grade 80 chain. It is safe for overhead lifting. Grade 100 chains includes designs embossed with a 10 or 100.

A newer product in the market, Grade 120 chain is up to 50% stronger than Grade 80 chain and 20% stronger than Grade 100 chain. It's also more resistant to abrasion than both Grade 80 and Grade 100 chains. It's safe for overhead lifts.

3. Learn more about the differences between grades 70, 80 and 100 here:

A common question our sales team hears from customers about our chain products is “What are the differences between grade 70, 80, 100, and 120 chain?” We explain the differences between these categories and which chains you should use according to your needs.

Grade 70 chain is manufactured in heat-treated carbon steel. Also known as "trucker's chain," people use grade 70 as tie-downs on over-the-road trailers. Never use this chain for overhead lifting.

This type generally features a gold chromate finish so it’s easy to recognize. It also meets California Highway Patrol and DOT requirements. The uses for this chain, apart from transportation, include towing, logging, oil rigs, and safety applications.

This chain includes designs embossed with 7, 70, or 700.

80 chain is a heat-treated steel chain with a high strength to weight ratio. Its strength makes it safe for overhead lifting and lifting slings. It’s also excellent for uses such as recovery, safety, and towing chains.

This chain is also becoming more common in the flatbed trucking industry to secure heavy-duty industrial loads. Because these types of chains are generally equipped with a specific type of clevis grab hook, and such chain assemblies are not approved for overhead lifting.

This chain includes designs embossed with 8, 80, or 800.

Grade 100 chain is a newer product and is becoming increasingly popular as a replacement for grade 80 chain. Considered premium quality by manufacturers, it provides about 25% higher working load limits than grade 80 and works for overhead lifting applications.

More people use grade 100 over grade 80 to secure flated loads. This chain contains an added strength and smaller size that does not go against the working load limit.

However, because these chains are generally equipped with a specific type of clevis grab hook, and such chain assemblies are not approved for overhead lifting.

This chain includes designs embossed with 10, 100, or 1000.

Grade 120 chain is also a newer category of high performance chain, offering the highest strength in the industry. The square link style creates more contact between the bearing surfaces on the links, which reduces pressure on the chain.

This translates to working load limits that are 50% higher than grade 80, and 20% higher than grade 100. Chain grade 120 works for overhead lifting. It's important to note that as with Grade 80 tie down chain assemblies and Grade 100 tie down chain assemblies, chain assemblies are also not safe for overhead lifting due to the type of hooks used.

This type of chain has a bright blue finish to make them easily recognizable.

Regardless of the type of chain, all must adhere to standards set by the National Association of Chain Manufacturers (NACM), which include:

- Never transporting or suspending lifted loads over people.

- Inspecting chains periodically for cracks, gouges, wear, elongation, nicks, and suitability.

- Excessive temperatures or exposure to chemically active environments such as acids or corrosive liquids or fumes can reduce a chain’s performance.

- Consult with the chain's manufacturer if chains will operate outside the recommended temperature range ( -40 °F to 400 °F).

- Remove chain from service if the thickness at any part on the link is less than the listed minimum value.

- When mixing chain or component types, all should be rated at the working load limit of the lowest-rated component or chain.

- Browse our selection of grade 70 transport chain, as well as chain slings.

Post time: Sep-27-2022