Mining Scraper Welded G 80 Chain

Mining Scraper Welded G 80 Chain

Introducing our Stainless Steel Welded Link Chain, a heavy-duty solution designed for industrial conveyor, lifting and mining applications. This versatile chain is made of high-quality alloy steel, ensuring superior strength and durability.

Ideal for heavy-duty industrial environments, our stainless steel welded link chains can easily handle the rigors of mining, metalworking, coal mining and a variety of other mining operations. Its rugged construction and corrosion resistance make it a dependable choice for efficient material handling and conveying.

The chain is designed with welded links for maximum strength and flexibility for smooth and efficient operation. The strong links are firmly welded together to provide long-lasting performance even in extreme conditions. Whether you need to move large loads, transport heavy materials or lift equipment, our stainless steel welded link chains can do the job.

Safety is a top priority in any industrial environment and our chains ensure reliable and stable operation. The chain's durable construction reduces the risk of accidents and ensures a safe and productive work environment. Its robust design makes it suitable for harsh conditions, including high temperatures and heavy loads.

Plus, our stainless steel welded link chains are resistant to wear and require very little maintenance. This saves you time and money as less maintenance means increased productivity and less downtime. The sturdiness of this chain guarantees a long service life, making it a cost-effective option in the long run.

We understand the different requirements of our customers and our Stainless Steel Welded Link Chains are available in different sizes and configurations. This allows for easy customization to meet your specific needs and ensures compatibility with your existing equipment.

Invest in our stainless steel welded link chains for a reliable, efficient solution to your industrial conveying, lifting and mining needs. With its exceptional strength, durability and versatility, this chain will enhance your operation, provide unmatched performance and ensure a safer work environment.

Category

Our mining chain measures 10*40mm, the perfect size to fit all kinds of mining equipment. It provides a safe and efficient method of moving material and equipment, making it an essential tool for any mining operation. The customizability of the chain makes it easy to adapt to different machines and applications.

Safety is always the top priority in the mining industry and our mining chain takes this aspect very seriously. It is designed to meet stringent safety standards, ensuring workers can perform tasks with confidence and peace of mind. The chain's robust construction minimizes the risk of accidents and reduces downtime due to equipment failure.

In conclusion, our alloy steel welded connection custom 10*40mm mining chain is a game changer for the mining industry. Its exceptional durability, strength and versatility make it an essential tool for any mining operation. Custom designed with welded connections and adhering to safety standards, the chain provides a reliable solution to the challenges facing the mining industry. Invest in our mining chain and experience the difference it can make for your mining operations.

Application

Related Products

Chain Parameter

SCIC Round Link Chain is made according to China GB/T-12718 standard and factory Technical Requirements, as well as to DIN 22252 or GOST 25996 standards and clients specs

SCIC Round Link Chain is used for Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), road header machines, coal plows and other equipment that requires this type of chain.

Anti-corrosive coatings (e.g., hot dipped galvanization) result in decreased chain mechanical properties, therefore the application of any anti-corrosive coatings shall subject to order agreement between buyer and SCIC.

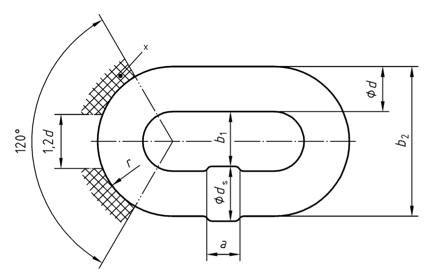

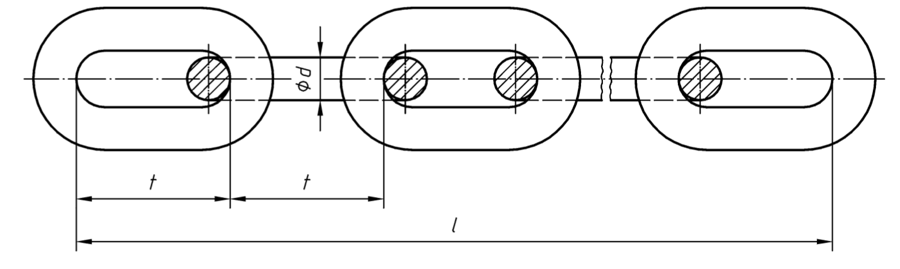

Figure 1: round link chain

Table 1: round link chain dimensions

|

link size (opp. Weld) |

pitch |

link width |

link weld size |

unit weight |

||||

|

nominal |

tolerance |

nominal |

tolerance |

inner |

outer |

diameter |

length |

|

|

10 |

± 0.4 |

40 |

±0.5 |

12 |

34 |

10.8 |

7.1 |

1.9 |

|

14 |

± 0.4 |

50 |

±0.5 |

17 |

48 |

15 |

10 |

4.0 |

|

18 |

± 0.5 |

64 |

±0.6 |

21 |

60 |

19.5 |

13 |

6.6 |

|

19 |

± 0.6 |

64.5 |

±0.6 |

22 |

63 |

20 |

13 |

7.4 |

|

22 |

± 0.7 |

86 |

±0.9 |

26 |

74 |

23.5 |

15.5 |

9.5 |

|

24 |

± 0.8 |

86 |

±0.9 |

28 |

79 |

26 |

17 |

11.6 |

|

26 |

± 0.8 |

92 |

±0.9 |

30 |

86 |

28 |

18 |

13.7 |

|

30 |

± 0.9 |

108 |

±1.1 |

34 |

98 |

32.5 |

21 |

18.0 |

|

34 |

± 1.0 |

126 |

±1.3 |

38 |

109 |

36.5 |

23.8 |

22.7 |

|

38 |

± 1.1 |

126 |

±1.3 |

42 |

121 |

41 |

27 |

30.1 |

|

38 |

± 1.1 |

137 |

±1.4 |

42 |

121 |

41 |

27 |

29.0 |

|

42 |

± 1.3 |

137 |

±1.4 |

48 |

137 |

45 |

30 |

36.9 |

|

42 |

± 1.3 |

146 |

±1.5 |

48 |

137 |

45 |

30 |

36.0 |

|

42 |

± 1.3 |

152 |

±1.5 |

46 |

133 |

45 |

30 |

35.3 |

|

notes: Larger size chain available upon inquiry. |

||||||||

Table 2: round link chain mechanical properties

|

chain size |

chain grade |

test force |

elongation under test force |

breaking force |

elongation at fracture |

minimum deflection |

|

10 x 40 |

S |

85 |

1.4 |

110 |

14 |

10 |

|

SC |

100 |

1.6 |

130 |

|||

|

SCC |

130 |

1.9 |

160 |

|||

|

14 x 50 |

S |

150 |

1.4 |

190 |

14 |

14 |

|

SC |

200 |

1.6 |

250 |

|||

|

SCC |

250 |

1.9 |

310 |

|||

|

18 x 64 |

S |

260 |

1.4 |

320 |

14 |

18 |

|

SC |

330 |

1.6 |

410 |

|||

|

SCC |

410 |

1.9 |

510 |

|||

|

19 x 64.5 |

S |

290 |

1.4 |

360 |

14 |

19 |

|

SC |

360 |

1.6 |

450 |

|||

|

SCC |

450 |

1.9 |

565 |

|||

|

22 x 86 |

S |

380 |

1.4 |

480 |

14 |

22 |

|

SC |

490 |

1.6 |

610 |

|||

|

SCC |

610 |

1.9 |

760 |

|||

|

24 x 86 |

S |

460 |

1.4 |

570 |

14 |

24 |

|

SC |

580 |

1.6 |

720 |

|||

|

SCC |

720 |

1.9 |

900 |

|||

|

26 x 92 |

S |

540 |

1.4 |

670 |

14 |

26 |

|

SC |

680 |

1.6 |

850 |

|||

|

SCC |

850 |

1.9 |

1060 |

|||

|

30 x 108 |

S |

710 |

1.4 |

890 |

14 |

30 |

|

SC |

900 |

1.6 |

1130 |

|||

|

SCC |

1130 |

1.9 |

1410 |

|||

|

34 x 126 |

S |

900 |

1.4 |

1140 |

14 |

34 |

|

SC |

1160 |

1.6 |

1450 |

|||

|

SCC |

1450 |

1.9 |

1810 |

|||

|

38 x 126 |

S |

1130 |

1.4 |

1420 |

14 |

38 |

|

SC |

1450 |

1.6 |

1810 |

|||

|

SCC |

1810 |

1.9 |

2270 |

|||

|

42 x 137 |

S |

1390 |

1.4 |

1740 |

14 |

42 |

|

SC |

1770 |

1.6 |

2220 |

|||

|

SCC |

2220 |

1.9 |

2770 |