Hardened Tooth Surface Conveyor Roller Chain Sprocket for Mining Machine

Hardened Tooth Surface Conveyor Roller Chain Sprocket for Mining Machine

Category

Application

Related Products

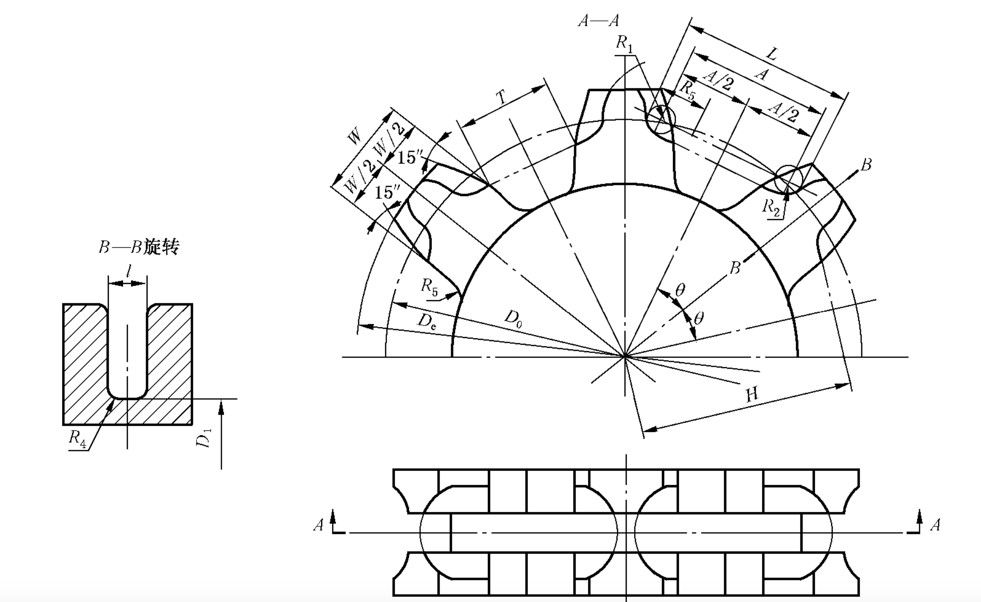

Round Link Chain Sprockets Parameter

SCIC round link chain sprocket is made to ISO 5613:1984 (mining-drive sprocket assemblies for chain conveyors) and equivalent Chinese standard GB/T 24503-2009 (mining-drive sprocket for round link chains). Round link chain sprocket is for use with twin outboard chain assemblies for chain conveyors, while the round chain links geometry is to DIN 22252, DIN 766 or ISO 610.

SCIC round link chain sprockets are also made to client’s particular design / dimensions, by the process and under SCIC quality control system:

- Moulding to ensure sprocket dimensions to approved drawings;

- Casting of alloy steel, with in-situ chemical composition analysis by spectrum;

- Heat-treatment of cast piece with connected mechanical test coupon;

- Mechanical property test with hardness check on heat-treatment;

- CNC machining of sprocket to fine accuracy;

- Sprocket teeth subject to induction heat treatment to reach hardness HRC 50-55.

|

Chain size |

Teeth number N |

Pitch circle dia. D0 |

Overall dia. (De) |

Groove dia. (Di) |

Groove width L |

Tooth radius R1 |

Root radius R2 |

Pocket plan radius R3 |

Groove radius R4 |

Root radius R5 |

Distance H |

Pocket length L |

Tooth thickness W |

Pocket centers A |

|||

|

Reference |

Max. |

Max. |

Reference |

Nominal |

Tolerance |

Max. |

Reference |

Reference |

Nominal |

Tolerance |

Nominal |

Tolerance |

Max. |

Reference |

|||

|

10x40 |

5 |

130 |

150 |

82 |

14 |

25 |

5 |

+0.5 / 0 |

5 |

5 |

55 |

0 / -1.5 |

63 |

+2 / 0 |

37 |

53 |

|

|

6 |

155 |

175 |

108 |

68.5 |

|||||||||||||

|

7 |

180 |

200 |

134 |

81.5 |

|||||||||||||

|

8 |

205 |

225 |

159 |

94.5 |

|||||||||||||

|

9 |

230 |

250 |

185 |

107.5 |

|||||||||||||

|

10 |

256 |

276 |

210 |

120.5 |

|||||||||||||

|

14x50 |

5 |

162 |

190 |

100 |

20 |

29 |

7 |

+0.5 / 0 |

25 |

7 |

7 |

67.5 |

0 / 1.5 |

82 |

+2 / 0 |

46 |

68 |

|

6 |

193 |

221 |

132 |

84.5 |

|||||||||||||

|

7 |

225 |

253 |

164 |

101 |

|||||||||||||

|

8 |

256 |

284 |

195 |

117.5 |

|||||||||||||

|

9 |

288 |

316 |

227 |

133.5 |

|||||||||||||

|

10 |

320 |

348 |

259 |

149.5 |

|||||||||||||

|

18x64 |

5 |

208 |

244 |

129 |

25 |

37 |

9 |

+0.5 / 0 |

30 |

9 |

9 |

86.5 |

0 / -1.5 |

105 |

+2 / 0 |

60 |

87 |

|

6 |

248 |

284 |

170 |

108 |

|||||||||||||

|

7 |

288 |

324 |

210 |

129 |

|||||||||||||

|

8 |

328 |

364 |

250 |

150 |

|||||||||||||

|

9 |

369 |

405 |

292 |

171 |

|||||||||||||

|

22x86 |

5 |

279 |

323 |

179 |

30 |

53 |

11 |

+0.5 / 0 |

38 |

11 |

11 |

118 |

0 / -1.5 |

136 |

+2 / 0 |

81 |

114 |

|

6 |

333 |

377 |

234 |

146.5 |

|||||||||||||

|

7 |

387 |

431 |

289 |

175 |

|||||||||||||

|

8 |

441 |

485 |

344 |

203 |

|||||||||||||

|

9 |

495 |

539 |

398 |

231 |

|||||||||||||

|

24x86 |

5 |

279 |

327 |

178 |

32 |

50 |

12 |

+0.5 / 0 |

40 |

12 |

12 |

116.5 |

0 / -1.5 |

140 |

+2 / 0 |

81 |

116 |

|

6 |

333 |

381 |

233 |

145.5 |

|||||||||||||

|

7 |

387 |

435 |

288 |

173.5 |

|||||||||||||

|

8 |

441 |

489 |

342 |

202 |

|||||||||||||

|

9 |

495 |

543 |

397 |

229.5 |

|||||||||||||

|

26x92 |

5 |

299 |

350 |

183 |

35 |

53 |

13 |

+0.5 / 0 |

45 |

13 |

13 |

124.5 |

0 / -1.5 |

151 |

+2 / 0 |

86 |

125 |

|

6 |

356 |

408 |

242 |

155 |

|||||||||||||

|

7 |

414 |

466 |

300 |

185.5 |

|||||||||||||

|

8 |

472 |

524 |

359 |

215.5 |

|||||||||||||

|

9 |

530 |

582 |

418 |

245.5 |

|||||||||||||

|

Chain size |

Teeth number N |

Pitch circle dia. D0 |

Overall dia. (De) |

Groove dia. (Di) |

Groove width L |

Tooth radius R1 |

Root radius R2 |

Pocket plan radius R3 |

Groove radius R4 |

Root radius R5 |

Distance H |

Pocket length L |

Tooth thickness W |

Pocket centers A |

|||

|

Reference |

Max. |

Max. |

Reference |

Nominal |

Tolerance |

Max. |

Reference |

Reference |

Nominal |

Tolerance |

Nominal |

Tolerance |

Max. |

Reference |

|||

|

30x108 |

5 |

351 |

411 |

218 |

40 |

63 |

15 |

+0.5 / 0 |

50 |

15 |

15 |

146 |

0 / -1.5 |

176 |

+2 / 0 |

101 |

146 |

|

6 |

418 |

478 |

287 |

182.5 |

|||||||||||||

|

7 |

486 |

546 |

356 |

218 |

|||||||||||||

|

8 |

554 |

614 |

425 |

253.5 |

|||||||||||||

|

9 |

623 |

683 |

494 |

288.5 |

|||||||||||||

|

34x126 |

5 |

409 |

477 |

263 |

44 |

75 |

17 |

+0.5 / 0 |

55 |

17 |

17 |

171 |

0 / -1.5 |

204 |

+2 / 0 |

117 |

170 |

|

6 |

488 |

556 |

343 |

213.5 |

|||||||||||||

|

7 |

567 |

635 |

423 |

255 |

|||||||||||||

|

8 |

647 |

715 |

504 |

296 |

|||||||||||||

|

9 |

726 |

794 |

584 |

337 |

|||||||||||||

|

38x137 |

5 |

445 |

521 |

285 |

50 |

80 |

19 |

+0.5 / 0 |

60.5 |

19 |

19 |

185.5 |

0 / -1.5 |

223 |

+2 / 0 |

128 |

185 |

|

6 |

531 |

531 |

372 |

231.5 |

|||||||||||||

|

7 |

617 |

693 |

460 |

276.5 |

|||||||||||||

|

8 |

703 |

779 |

547 |

321.5 |

|||||||||||||

|

9 |

790 |

866 |

634 |

366 |

|||||||||||||

|

42x146 |

5 |

474 |

558 |

300 |

54 |

83 |

21 |

+0.5 / 0 |

66.5 |

21 |

21 |

196.5 |

0 / -1.5 |

241 |

+2 / 0 |

136 |

199 |

|

6 |

566 |

650 |

393 |

245.5 |

|||||||||||||

|

7 |

657 |

741 |

486 |

294 |

|||||||||||||

|

8 |

750 |

834 |

579 |

341.5 |

|||||||||||||

|

9 |

842 |

926 |

672 |

389 |

|||||||||||||

|

42x152 |

5 |

494 |

578 |

318 |

54 |

89 |

21 |

+0.5 / 0 |

66.5 |

21 |

21 |

206 |

0 / -1.5 |

247.5 |

+2 / 0 |

142 |

205.5 |

|

6 |

589 |

673 |

416 |

257 |

|||||||||||||

|

7 |

684 |

768 |

512 |

307 |

|||||||||||||

|

8 |

780 |

864 |

610 |

356.5 |

|||||||||||||

|

9 |

876 |

960 |

706 |

406 |

|||||||||||||

|

48x152 |

5 |

494 |

590 |

318 |

62 |

80 |

24 |

+0.5 / 0 |

82 |

24 |

24 |

202 |

0 / -1.5 |

259.5 |

+2 / 0 |

142 |

211.5 |

|

6 |

589 |

685 |

416 |

253 |

|||||||||||||

|

7 |

684 |

780 |

512 |

303.5 |

|||||||||||||

|

8 |

780 |

876 |

610 |

353 |

|||||||||||||

|

9 |

876 |

972 |

706 |

403 |

|||||||||||||

To further meeting clients unique request on round link chain wheels and sprockets, we are capable of designing and fabricating specifically to your conveyor and bucket elevator specifications, chain wheels in toothed and toothless, cast and forged, completed with full dimensional control and trial fit test with round link chains, mechanical test to determine the material tensile strength and hardness.

Photos of our supply reference:

12 teeth pocket sprocket

5 teeth sprocket

8 teeth pocket sprocket

14 teeth key sprocket

13 teeth key sprocket

15 teeth assembly sprocket