100kn Alloy Steel Link Welded Lashing Lifting Mining Chain

100kn Alloy Steel Link Welded Lashing Lifting Mining Chain

Introducing our revolutionary 100kn Alloy Steel Ring Welded Lashing Lifting Mining Chain, the perfect solution for all your mining and lifting needs. Our manufacturer is our highly respected company that has been a pioneer in the industry for 30 years, we consistently meet the changing needs of China's chain manufacturing industry, especially in mining, heavy lifting and industrial conveying.

Our 100kn alloy steel ring welded lashing hoist mining chains are designed to withstand extreme conditions and provide unmatched strength for rigorous mining operations. Made of high-quality alloy steel, the chain is durable, ensuring durability and reliability even in the harshest environments. With a maximum load capacity of 100kn, it has excellent lifting capacity and is an essential tool for heavy lifting operations.

The chain features welded lashing links for extra security when lifting heavy loads, giving you peace of mind that your equipment and materials are securely secured. Each link has been carefully designed and manufactured to meet and exceed the highest industry standards, ensuring maximum safety and efficiency during your operation.

Our 100kn Alloy Steel Ring Welded Lashing Lifting Mining Chains are the result of years of research and development, combining cutting edge technology with our vast knowledge and expertise. We understand the unique challenges facing the mining and industrial sectors and are committed to providing the most reliable and high performing chain to meet your specific requirements.

In our state-of-the-art facility, we employ a strict quality control system, ensuring that each chain is thoroughly inspected before leaving our premises. Our commitment to excellence and customer satisfaction drives us to provide the highest quality products that consistently meet and exceed industry expectations.

Invest in our 100kn Alloy Steel Ring Welded Lashing Lifting Mining Chain and experience the difference in performance and reliability. Join our long list of satisfied customers who trust us for their mining & lifting needs. Contact us today to learn more about our products and how we can help you achieve your goals. Let us be your successful partner.

Category

Round link chain, round steel link chain, round link mining chain, DIN 22252 mining chain, mining conveyor chain, flight bar chain system

Application

Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), road header machines, coal plows, etc.

As the No. 1 coal production country, China has seen demand of huge quantity round link mining chains, and thus been encouraging China round steel link chain manufacturing capacity in terms of quantity and quality. SCIC’s chain factory with its 30 years round steel link chains production history has been fully involved into China coal industry supply; our round link chains have been so far well accepted and used by all the main coal & mining companies through China.

Our round steel link chain quality is ensured through each step of chain production, from sound alloy steel bars to precise link fabrication by robot, from computerized flash butt welding to well designed quenching & tempering heat-treatment (resulting in desired strength and surface hardness), from proof test to mechanical tests on verifying the surface & inner quality.

SCIC round link chain is made according to China GB/T-12718 standard and factory Technical Requirements, as well as to DIN 22252 or GOST 25996 standards and clients specs

SCIC round link chain is used for Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), road header machines, coal plows and other equipment that requires this type of chain.

Anti-corrosive coatings (e.g., hot dipped galvanization) result in decreased chain mechanical properties, therefore the application of any anti-corrosive coatings shall subject to order agreement between buyer and SCIC.

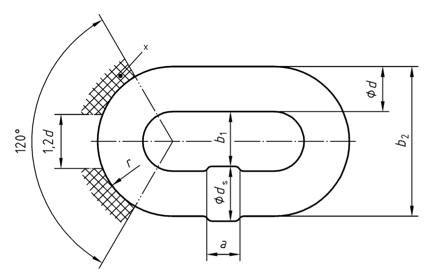

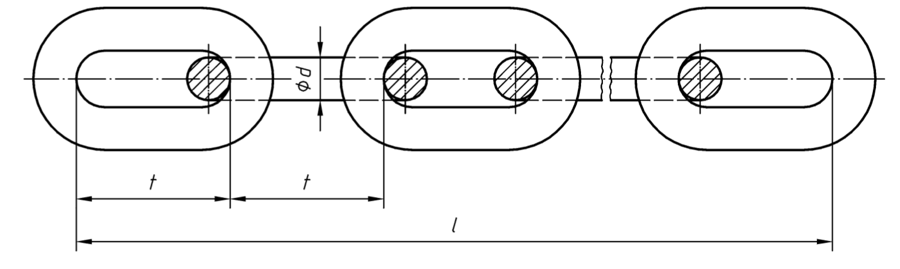

Figure 1: round link chain

Table 1: round link chain dimensions

|

link size (opp. Weld) |

pitch |

link width |

link weld size |

unit weight |

||||

|

nominal |

tolerance |

nominal |

tolerance |

inner |

outer |

diameter |

length |

|

|

10 |

± 0.4 |

40 |

±0.5 |

12 |

34 |

10.8 |

7.1 |

1.9 |

|

14 |

± 0.4 |

50 |

±0.5 |

17 |

48 |

15 |

10 |

4.0 |

|

18 |

± 0.5 |

64 |

±0.6 |

21 |

60 |

19.5 |

13 |

6.6 |

|

19 |

± 0.6 |

64.5 |

±0.6 |

22 |

63 |

20 |

13 |

7.4 |

|

22 |

± 0.7 |

86 |

±0.9 |

26 |

74 |

23.5 |

15.5 |

9.5 |

|

24 |

± 0.8 |

86 |

±0.9 |

28 |

79 |

26 |

17 |

11.6 |

|

26 |

± 0.8 |

92 |

±0.9 |

30 |

86 |

28 |

18 |

13.7 |

|

30 |

± 0.9 |

108 |

±1.1 |

34 |

98 |

32.5 |

21 |

18.0 |

|

34 |

± 1.0 |

126 |

±1.3 |

38 |

109 |

36.5 |

23.8 |

22.7 |

|

38 |

± 1.1 |

126 |

±1.3 |

42 |

121 |

41 |

27 |

30.1 |

|

38 |

± 1.1 |

137 |

±1.4 |

42 |

121 |

41 |

27 |

29.0 |

|

42 |

± 1.3 |

137 |

±1.4 |

48 |

137 |

45 |

30 |

36.9 |

|

42 |

± 1.3 |

146 |

±1.5 |

48 |

137 |

45 |

30 |

36.0 |

|

42 |

± 1.3 |

152 |

±1.5 |

46 |

133 |

45 |

30 |

35.3 |

|

notes: Larger size chain available upon inquiry. |

||||||||

Table 2: round link chain mechanical properties

|

chain size |

chain grade |

test force |

elongation under test force |

breaking force |

elongation at fracture |

minimum deflection |

|

10 x 40 |

S |

85 |

1.4 |

110 |

14 |

10 |

|

SC |

100 |

1.6 |

130 |

|||

|

SCC |

130 |

1.9 |

160 |

|||

|

14 x 50 |

S |

150 |

1.4 |

190 |

14 |

14 |

|

SC |

200 |

1.6 |

250 |

|||

|

SCC |

250 |

1.9 |

310 |

|||

|

18 x 64 |

S |

260 |

1.4 |

320 |

14 |

18 |

|

SC |

330 |

1.6 |

410 |

|||

|

SCC |

410 |

1.9 |

510 |

|||

|

19 x 64.5 |

S |

290 |

1.4 |

360 |

14 |

19 |

|

SC |

360 |

1.6 |

450 |

|||

|

SCC |

450 |

1.9 |

565 |

|||

|

22 x 86 |

S |

380 |

1.4 |

480 |

14 |

22 |

|

SC |

490 |

1.6 |

610 |

|||

|

SCC |

610 |

1.9 |

760 |

|||

|

24 x 86 |

S |

460 |

1.4 |

570 |

14 |

24 |

|

SC |

580 |

1.6 |

720 |

|||

|

SCC |

720 |

1.9 |

900 |

|||

|

26 x 92 |

S |

540 |

1.4 |

670 |

14 |

26 |

|

SC |

680 |

1.6 |

850 |

|||

|

SCC |

850 |

1.9 |

1060 |

|||

|

30 x 108 |

S |

710 |

1.4 |

890 |

14 |

30 |

|

SC |

900 |

1.6 |

1130 |

|||

|

SCC |

1130 |

1.9 |

1410 |

|||

|

34 x 126 |

S |

900 |

1.4 |

1140 |

14 |

34 |

|

SC |

1160 |

1.6 |

1450 |

|||

|

SCC |

1450 |

1.9 |

1810 |

|||

|

38 x 126 |

S |

1130 |

1.4 |

1420 |

14 |

38 |

|

SC |

1450 |

1.6 |

1810 |

|||

|

SCC |

1810 |

1.9 |

2270 |

|||

|

42 x 137 |

S |

1390 |

1.4 |

1740 |

14 |

42 |

|

SC |

1770 |

1.6 |

2220 |

|||

|

SCC |

2220 |

1.9 |

2770 |